Logistical Delays Putting the Cold Chain Under Pressure

In the international transport of frozen products, transit time has become a critical factor. Between geopolitical tensions, port congestion, and infrastructure constraints, logistical delays sometimes extend by several days, significantly increasing the risk of cold chain disruption.

This phenomenon affects both sea and air transport, forcing exporters to strengthen their temperature traceability strategies and rely on reliable monitoring tools.

Frozen Products: An Absolute Quality Requirement

Premium frozen products — artisanal pastries, dairy products, fruits, or bakery products — require impeccable thermal control from departure to final delivery.

In this context, traceability is no longer performed “in case of doubt”: temperature data is systematically analyzed to prove transport compliance and secure commercial transactions.

Data even becomes an economic argument: in some cases, the temperature report conditions the payment for the goods.

Air Transport of Frozen Products: Constraints Similar to Pharmaceuticals

Some frozen products are transported with dry ice to maintain extremely low temperatures.

However, this solution imposes:

- strict quantity limits per package

- specific safety rules

- compliance with IATA standards

Poor management can compromise product quality even before arrival, hence the importance of precise and documented monitoring.

Longer Routes = Higher Risks

Today, a sea journey that used to take about 20 days can now extend to 25 days or more.

Another difficulty: in some ports, the number of electrical outlets to power refrigerated containers is insufficient, necessitating connection rotations with a risk of temperature increase.

In these situations, the temperature recorder becomes the only reliable proof of what actually happened during transport.

Why Traceability is Becoming a Global Standard

Thermal traceability is gradually becoming an international standard. Some importers now require a temperature recorder on each shipment, or even provide the devices themselves to exporters.

This evolution is explained by the growing challenges related to:

- regulatory compliance

- food safety

- contractual liability

- protection of market value

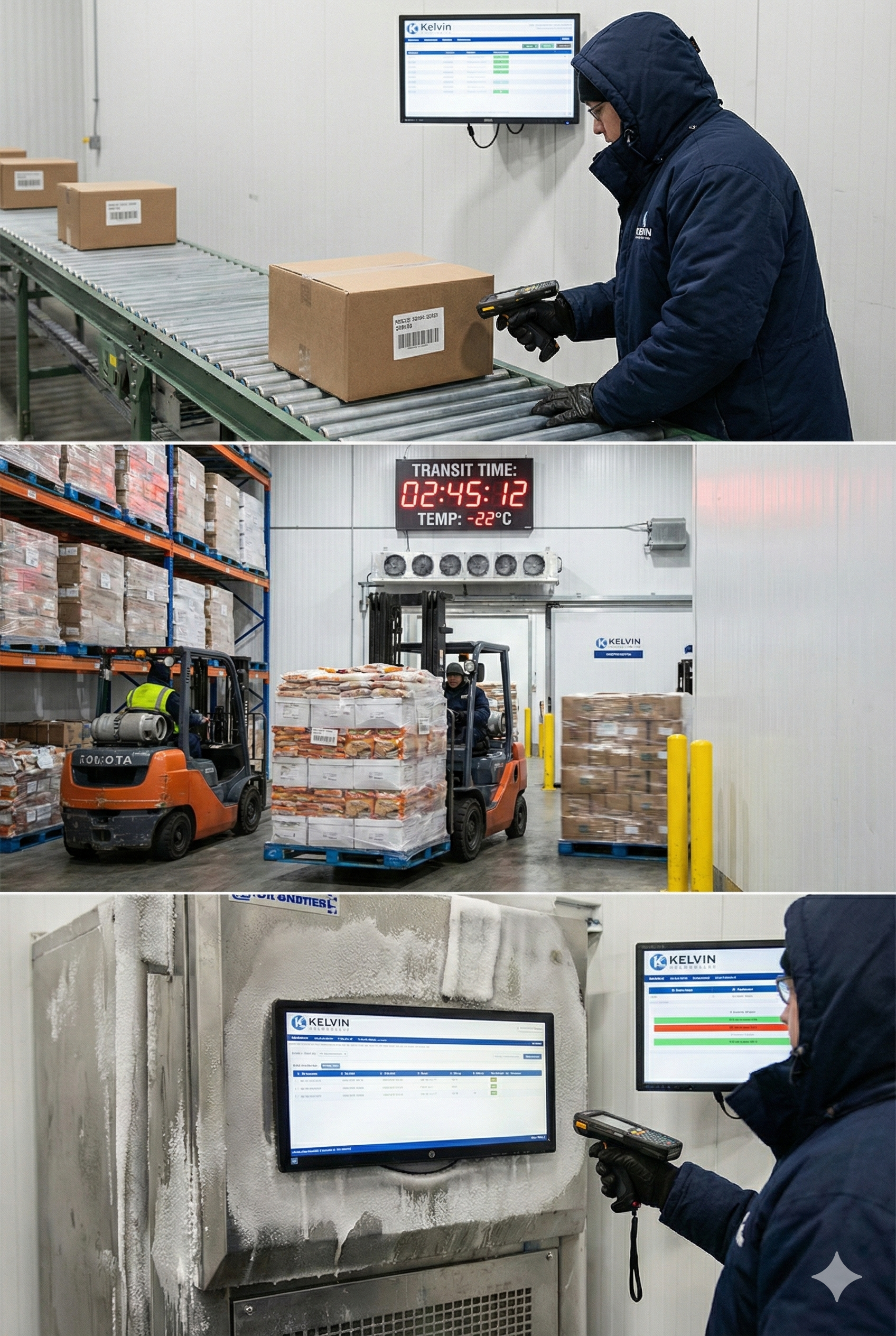

Data: A New Pillar of Logistical Performance

Digitalization now allows for:

- centralizing temperature reports

- analyzing transport histories

- identifying risky routes

- optimizing logistical decisions

Cloud platforms allow for archiving and utilizing this data to improve the overall performance of the supply chain.

Why Transit Time Has Become a Strategic Issue

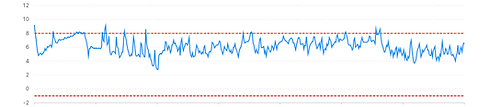

The longer the transport time, the higher the risk of thermal variation. Frozen products must generally remain below –18 °C to guarantee their quality and sanitary safety.

Even a short exposure to a higher temperature can alter texture, quality, and shelf life.

With the lengthening of transit times, mastering the cold chain becomes a strategic issue for exporters of frozen products.

Temperature traceability is no longer just a technical tool: it becomes a lever for compliance, financial security, and logistical optimization in an increasingly demanding international trade.